Designing a SCADA System

16 Sept, 2021.

In this post, we will understand how to properly design a SCADA system and steps to consider when doing it. (Click on the images for a more zoomed view)

Many programmers get excited when they are asked to design a SCADA system from scratch. The ideas of new color, graphical schematics and other designs run on their mind. Obviously, showing a large plant operation on the SCADA screen is a big task and requires proper knowledge of various graphical interfaces and basic features which must be shown; so that the system looks aesthetic and great to operate. Because SCADA is used for large scale applications, it will be good if all the basic features and also proper details of the instruments are shown on screen.

In this post, we will some basic design steps and factors to see when designing a SCADA graphic interface.

Screen Designing:

1. Welcome Page:

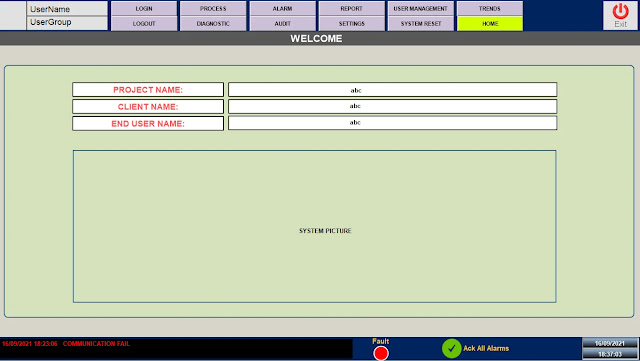

The first page that appears to an operator when the SCADA runtime starts is the welcome page. In this page, you need to properly mention the details like system name, client name, end user name, logo of the client and a clear picture of the system. A properly designed welcome page is the first impression in engaging the operator. Refer the below image for reference.

2. Header and Footer:

When you are navigating a SCADA runtime, improper and unrequired navigations can irritate the operator. Firstly, impose that buttons on the header and footer which will be frequently clicked and which are of utmost importance to them. Like you navigate a mobile smartphone, where important buttons are given on the top and bottom of the screen; use similar kind of logic when designing a header and footer. According to me, the following buttons will be required which will properly help the user in navigating the system – login, logout, home, process selection, diagnostics of PLC IO’s, alarm, audit trail, report, settings (critical), user management, exit, system reset (if applicable), trends, alarm acknowledge, fault indication, user name indication, user group indication, date & time and alarm banner. This buttons are generally given in every SCADA system and it also varies depending on the programmer who is developing it. Refer the above image for reference. Also, give color animation to the button which is selected. Taking an example of the above image, if I am on welcome or home page, then the home button is highlighted with separate color apart from remaining buttons. This will show the operator which screen he is present on right now.

3. Proper Access to buttons and screens:

Well, this is one of the most important criteria when navigating and controlling the operation. Unauthorized access to users for a particular button can prove to be dangerous. So, depending on the user level, assign proper access to each and every button as the safety of the plant operation is also an important factor.

4. Process Selection:

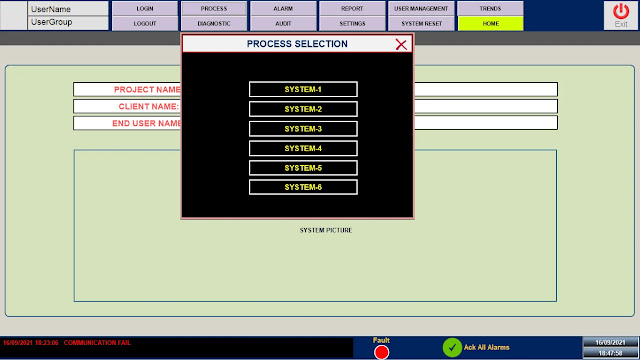

Generally, a SCADA runtime will control various processes of a plant. So, proper system selection buttons should be given so that the operator can go that particular system selected. Also, try to see that when you are in a particular system, no navigation is given to some other system through a button click. This will keep the navigation part neat and clean. Refer the below image for reference.

5. Diagnostic Screen:

PLC IO’s must be shown properly in SCADA with it’s addresses. This will help in diagnosing the user in case of any problem. Also, don’t forget to add spare addresses. Most of the programmers do not add it. Adding spare addresses will show the user how many IO’s are spare in the IO list. Add a button for simulating each digital input as shown in right side of the input name (refer below image).

6. Alarm Screen:

Show properly configured alarm lists and history in SCADA runtime. Also, add an alarm banner as discussed earlier to show the current alarm to the user irrespective of the page he is in.

7. Proper Configuration of Audit Trail and Reports:

This option depends on the application or if it is required or not. Suppose you are using Sensor-1 tag name. Then, ensure that you use the same name in audit logging or data logging in reports. Wrong names can confuse the user. Apart from this, remember one thing that the same name should be used everywhere in the runtime or wherever applicable.

8. Proper configuration of numeric displays:

Refer the below image. A most common mistake programmers do is invalid numeric decimal display of a particular tag in various pages. For example, there are two pages. In the first page, for a particular tag, you have given a single decimal and in the other page, you have mistakenly assigned two decimals. Do not do it. Always ensure that you maintain the same decimal point for a tag in the whole runtime display.

9. Trends:

Assign proper trend of a particular tag. Trends are useful for operators in tracking the behavior of that tag in the whole runtime history. Configure it’s history, tag range or scales properly.

10. Plant Layout Display:

Plant layout is the most important page of SCADA runtime. Refer the below image. It will be useful if you consider following things - properly align lines with the instruments, give proper instrument name, give arrow indication in running condition on the lines, show arrow indication from or to the system the line is coming or going, ensure proper animation of the instruments, ensure proper decimal of the instruments, and mainly, give proper color schematic in the screen. Always refer the P&ID given and ensure that each and every automation details are shown properly.

Communication Settings:

When you are handling such a large SCADA system, it’s communication with PLC is an important factor. Every software has it’s own configuration settings. Try to ensure that you set the parameters in such a way that the screens load faster and the tag values update quickly to the operator. Also, any command from the operator should also go quickly to the PLC. So, communication plays an important role in designing SCADA system.

Automatic Runtime Startup on PC Restart:

Ensure that your SCADA runtime starts automatically when the PC restarts. The operator should not come to start the runtime.

21CFR Standards:

Many customers require 21CFR compliance in SCADA system. Ensure that you set the PC settings and SCADA settings properly so that the runtime works accordingly.

Screen Resolution and SCADA tag count selection:

SCADA screens are designed based on screen resolution of the PC and the IO tag count. Ensure that you set the resolution and IO tag count properly in the SCADA backup before starting to design it.

System Architecture screen in SCADA page:

It would be helpful if you show system architecture page in the SCADA screen design. It refers to the communication link animation between PLC, SCADA and other communication equipment. Additionally, also try to give hardware and communication error faults in the SCADA alarm configuration.

I have covered the general principle of SCADA designing. I have also not attempted to cover every theory of these design deeply; you can learn it easily once you get familiar with them. I have just given you an insight of these types of controls. A great software and graphic understanding is required by the engineer who is designing such system. Learn the basics and explore a new type of study in this type of automation.

Thank you guys; I hope you enjoyed reading the practices normally used for this type of study in industrial automation.

The content of your blog is exactly what I needed, I like your blog, I sincerely hope that your blog a rapid increase in traffic density, which help promote your blog and we hope that your blog is being updated.

ReplyDeleteSteel Rack Manufacturer in China.

This blog was very informative.

ReplyDeleteplease visit our website for automation parts

http://www.iautomation.in/

Online automation component supply store. Get all your automation needs; served at one place. VFD, HMI, PLC, Sensors, Switches, controllers from all leading brands

Really Nice Information It's Very Helpful Thanks for sharing such an informative post.

ReplyDeletehttps://www.vyaparinfo.com/looking-for-bulk-buyers-in-india/

https://www.vyaparinfo.com/looking-for-distributors/

https://www.vyaparinfo.com/manufacturer/

Thanks for sharing useful post. to know more about:

ReplyDeletePLC SCADA in Delhi

Solidworks Training in Delhi

Summer Training

Excellent Blog

ReplyDeleteThanks for this wonderful blog it is very useful content for us. Visit my website to get best Information About Data Science Training in Noida and mention Below Technologies.

Python Training in Noida

Data Science Training in Noida

java Training in Noida

full stack Development Training in Noida

Software Testing Training in Noida

Summer Training in noida

Web Development Training in Noida

Kudos to you for maintaining such a fantastic blog. Your articles are always well-researched, informative, and enlightening. I appreciate the effort you put into sharing your expertise with the world! CETPA Infotech offers reputable Summer Training programs for students and professionals. These programs focus on practical skills, industry exposure, and bridging the gap between theory and application. With experienced trainers, participants work on real projects and gain hands-on experience in fields like software development, data science, and artificial intelligence.

ReplyDelete