Difference Between Isolated and Non-Isolated PLC Modules

11 Oct 2020.

In this

post, we will clarify the difference between isolated and non-isolated PLC

analog modules; and understand why isolation plays an important role in 4-20 mA

current loops. (Click on the images for a more zoomed

view)

Hello programmers. You all must be

familiar with the two widely used types of analog signals – 0-10 V and 4-20 mA.

Of these, the most popular one that is used is the 4-20 mA type one. The wiring

is simple; you have transmitters where only two wires are needed

(loop-powered). It can be run over long distances with minimum drop; voltage

drops much across long distance wires as compared to current drop. A varying

current loop load impedance will not affect the signal if it does not exceed

required component limits. Electromagnetic interference affects current loop at

a much lower rate as compared to voltage circuit.

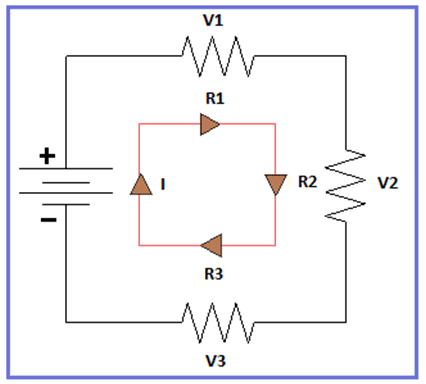

All the above advantages can be explained by simple Ohm’s law – V=I*R. Let’s see the below image. The circuit consists of a power supply and three loads. The power supply will give the voltage required to drive the current loop. Through current passing across each load, voltage drop occurs each of them and will vary according to the resistance available. However, current remains the same in the whole circuit. That is why; current is the most reliable source of information available for data.

Now consider the below image for the

understanding of current loop. The sensor provides the physical signal and the

transmitter acts as a transducer which converts this physical signal into

electrical current signal. For this signal to be produced first, a power source

is required. The loop is nothing but the wiring which carries the signal from

transmitter to receiver and then back to it. The value of the cable resistance

is directly proportional to the distance of transmission. If 0-10 V is

transmitted over long distance, there will be a drop in voltage due to

resistance of the cable; and the signal received will not be accurate. So, 4-20

mA is the main reason for it’s wide scale use.

But every technology has it’s pros and cons. The current type has high power consumption compared to other analog signal types. Increasing circuit load resistance will reduce the supply voltage available to power the transmitter that is generating the current signal. One of the major concerns of 4-20 mA is non-isolation. This single reason affects the use of this signal. We will investigate this theory and understand how an isolated PLC module improves the overall efficiency of the signal transmission as compared to a non-isolated PLC module.

Theory of analog isolation:

What is isolation in PLC?

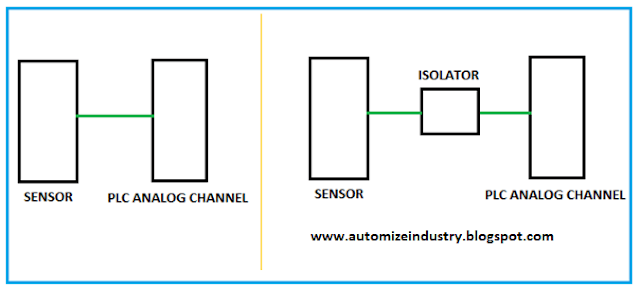

First, what is isolation? Isolation is

used to protect circuitry and human beings, break ground loops, and improve

common-mode voltage and noise rejection performance. See the below image. The left-hand

side image shows that a sensor is directly connected to analog input channel;

whereas the right-hand side image shows that the sensor is connected to the

channel via an isolator. The isolator protects the channel from any power/noise

fluctuations on the sensor side. It only filters the proper analog signal to

the channel and removes the spikes and fluctuations in it’s input side.

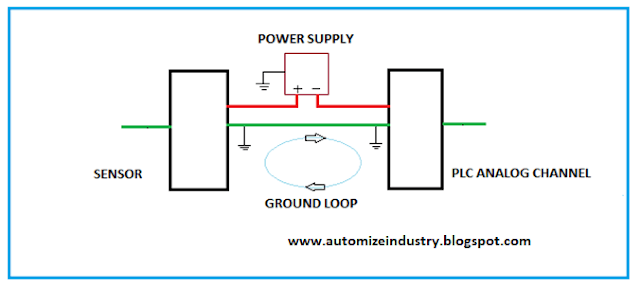

Ground loop leakage in 4-20 mA:

It’s other important use is to avoid

ground loop leakage. A ground loop current is nothing but the current flowing

from one signal ground in a circuit to another signal ground at a different

voltage potential. Most analog (4 to 20) mA loops are grounded at a single

point. Problems occur when there is more than one grounding point because earth

potentials will not be the same. This means current will flow between earth

points causing errors or noisy signals. This causes unpredictable signal

fluctuations and will often average the process signals, which causes reduction

in actual input/output with respect to channel. It can be like; you are

providing 16 mA from PLC analog output, but the field device is functioning at

12 mA. This problem is mostly faced in loads with high impedance. So,

installing an isolator in between will eliminate ground loop leakage, as the

isolator isolates channel and ground.

What are the different types of isolation?

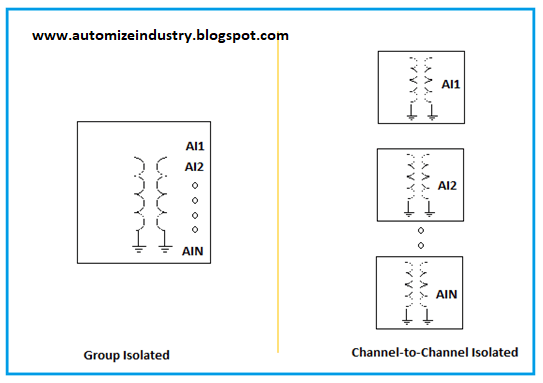

PLC channels can be isolated either by

connecting an isolator in the current loop circuit; or using an isolated PLC

module. Isolation is mostly achieved by galvanic isolation. Galvanic

isolation is the principle of physically and electrically separating two

circuits, so that there is no direct conduction path, but data and power can

still be exchanged. This is typically achieved by using transformers,

optocouplers, or capacitors. Refer the below image for understanding. As we

know an individual isolator, let’s investigate an isolated PLC module. There

are two types of isolation generally used in PLC modules – group isolation and

channel-to-channel isolation. In group isolation, all the channels are grouped

together to share a single isolation barrier, including power isolation and

signal isolation. But here, common-mode voltage difference arises between

channels in the group; meaning they should be placed in same zone. To eliminate

this problem, channel-to-channel isolation is used. In this, every channel has

it’s individual power isolation and signal isolation. This means that channels

are isolated from each other and any damage to a particular channel won’t

affect the other ones.

Isolated vs non-isolated analog input:

A common question most programmers ask

is how to choose between an isolated and non-isolated analog input. Mostly, in

all the PLC’s, when you choose a module between isolated and non-isolated;

remember that non-isolated means there is no isolation between channels and

isolated means there is isolation between individual channels. Remember that

channel to ground isolation is provided by default.

I would not go deep into ground loop

theory, isolation methods and need for isolation. It is very vast and would

take a lot of time for you to study. But it’s important to first understand the

concept behind isolation in analog circuitry. It basically protects the channel

from external damage. Also, this does not mean that you don’t have to use a

non-isolated module. It is cheaper than an isolated module and will work

properly too; provided the loop design has been thoroughly analyzed and made

accordingly, to avoid problems that are only realized when trying to get the

system up and running. There are numerous electrical methods in grounding the

system properly and securing it with safety too, which will properly utilize

the non-isolated module. The topic that I have written covers both analog

inputs and outputs.

I have covered the general theory

related to isolation and the difference between isolated and non-isolated

modules. I have also not attempted to cover every type of features deeply.

I have just given you an insight of this type of study. Learn the basics and

explore a new type of theory in this type of automation.

Thank you, guys; I hope you enjoyed reading the practices normally used for this type of study in industrial automation.

Comments

Post a Comment

If you have any queries, please let me know