Memory Backup and Restore in Schneider PLC

19 July, 2020.

In

this post, we will cover the basic topics on how to backup memory data of

variables from PLC and restore memory data of variables to PLC. (Click on

the images for a more zoomed view)

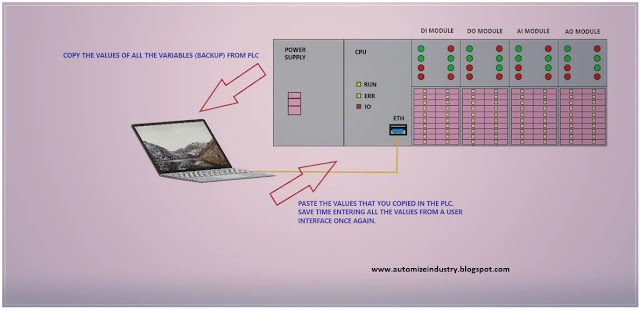

Hello programmers. Many a times, we come across some screens in a user interface (HMI or SCADA) which are password-protected and not accessible to users. These screens have some critical settings of the machine, which if modified, can affect the operation of a machine to a very great extent. Now, as you know, downloading a backup in the PLC resets all the values to it’s default values. If you want to download a backup in such type of PLC’s where you don’t know the critical settings as mentioned earlier, then you would be stuck up. In such a case, almost all the PLC’s provide a feature named backup (save) and restore data from / to PLC. It even saves your time which is wasted by entering all the last known values manually in the user interface. Just copy the values, store somewhere in your desktop PC and paste it when required. Follow this procedure of saving data every time before you download a backup in PLC and then restore back to it. It is a great tool to save time and increase overall efficiency of the system.

PLC program backup and storage:

It is extremely important for PLC programmers to save a

backup of the data and program, and restore them when downloading something.

What happens usually is after commissioning, we do not know how the operators

are running a plant. One fine day you will get a call that their system is not running

and will ask you to visit immediately. Maybe this call would come for example

after 3 years, and when you visit, you are sure you will not remember the exact

set values that you had entered during commissioning. This will put you in a dilemma.

In such case, if you had copied the last PLC values from the PLC before leaving

commissioning stage, you could have just pasted them in the PLC and your work

would have been done. You can also backfire the customer that they had entered

the values which were not the same during commissioning, and can help you from

any blame.

One more advice is to maintain scheduled PLC backup. Many

PLC’s have the option for automatic scheduled backup in a certain frequency.

This saves frequent data backup in the PC path and helps the operators in case of

any failure. Once you have the backup, you can then restore or paste it in the

PLC whenever required. Thus, the downtime of the machine and overall

maintenance costs are reduced for the customer and helps build trust with your

service.

Schneider PLC backup and restore:

We will study this feature in Schneider PLC. We will see how

to backup and restore data in Unity Pro and SoMachine V4.3. The format in which

the data is saved varies from software to software.

Let’s start by referring the Unity Pro software. Have a look

at the video below. The memory data from PLC is stored in. DTX format.

Normally, this procedure must be followed by keeping the PLC in stop mode. If

the PLC is in RUN mode, the saving of data from the PLC to a file may need

several application cycles and the data, in the file, may be de-synchronized,

which may affect application execution during restoration. I have completed the

process in run mode; but it’s strongly recommended to do this in stop mode. I

have just given an example on what are the steps that needs to be followed. The

PLC must be loaded with an application and you must be online and connected to

the PLC. As you can see in the video, unlocated variables and function block

instances are also saved. You must define the address range of the variables

for those which have addresses assigned to them. For restoring data, it is

recommended that the PLC be in stop mode.

How

to Backup and Restore Memory in Unity Pro

Now, let’s refer the So Machine V4.3 software. Check the

video below. Here, I have put the PLC in stop mode and then did the procedure.

In the video, as you can see, you can select the variables which you want to

backup. I have completed the procedure for just two variables – var_1 and var_2.

You have complete rights on how much variables you want to backup and restore.

How

to Backup and Restore Memory in Somachine V4.3

I have covered the general principles which normally are followed to backup and restore memory data with respect to PLC. I have also not attempted to cover every type of software; you can learn it easily in the software help file or internet. Use this procedure to save your time and without worrying about the values which has to be entered in a user interface after downloading.

Thank you, guys; I hope you enjoyed reading the practices

normally used for this type of study in industrial automation.

Comments

Post a Comment

If you have any queries, please let me know