HART Configuration in Schneider PLC

2 August, 2020.

In this

post, we will understand how to configure a HART device in a Schneider (M580)

PLC.

Hello programmers. Welcome back to our

study. I hope you enjoyed reading the first part on understanding the HART

protocol in general.

Let’s get a look now on how to configure a HART device

in a Schneider PLC (M580).

First of all, the most crucial

requirement is a proper DTM/DD file as discussed in the first part. Be it any PLC, an improper DTM/DD file of the HART

device cannot help you make a connection with it. To find that proper file, you

need to be well versed with the terms – HART universal revision and device

revision. In simpler terms, you can co-relate it with a firmware version of the

PLC. If you read the technical documentation of that device, you will find it’s

default HART universal revision and it’s own revision number (device revision).

They have options to select the revision according to your needs. You can set

them via a HART communicator tool or manually by entering the parameters in the

device menu shown on it’s display.

Let me explain you with the

device that I have used here for study. I have used Rosemount 3051-T pressure

transmitter (Emerson-make), which is

HART-enabled. Refer the below image. The default settings in this device are –

HART revision 5 and device revision 9. If you visit the website of Emerson for downloading the DTM file,

then you will find various versions of all the devices. Selecting the right one

requires sound knowledge of the specifications of device. When you download a

given link, most of them have a readme

file in it; which shows the supported devices in the DTM file and other

information related to HART communication. You can use it for confirmation.

Many a times, you cannot find a DTM file for a specific device; you can then

use a general DTM file of that manufacturer or confirm with them about the DTM

file for any issues.

After you have installed the software (DTM file setup), you have to update this DTM file in the PLC software. Without updating the DTM catalog, you cannot see this file in the software. For the PLC which we are referring here, use Unity Pro V13.1 or above. The software versions mentioned are stable and proper for HART communication. Now, refer the below video.

I will

explain it in the following steps:

· In the Tools

option, go to Hardware Catalog.

· Then, go to DTM catalog

inside it. You can see four sub-topics

under it – Device Types, vendors, groups and protocols. In

the protocols section, go to HART. I had already updated the DTM

file earlier; that’s the reason the device name is showing here (3051 HART 5). For first timers, you

will find that the device type you want is not installed. So, click the Update button below. After updating,

you will find the device name. This indicates that the device DTM file has been

installed successfully in the PLC software.

After the DTM has been successfully installed, you can now assign to it any PLC channel for use. Refer the below video.

I will

explain it following steps:

· We will use BMEP582040

CPU for study. The security features are initially disabled in the CPU. You

will need to unlock it.

· Now, set the IP address of the CPU. When you validate it,

it will ask for a service to be enabled (TFTP). So, unlock / enable all the

security options and tick all of them as shown.

· Then, add the BMEAHI0812

module in the slot required. Only 4-20 mA option is available in this module as

per HART protocol. You can scale the raw counts as required by you.

· Now, go to DTM

Browser in Tools option. Right

click the BMEP58_ECPU_EXT option and

click Add. You have to add the

analog module here. Select the module as shown and add it.

· Double click the BMEP58_ECPU_EXT

option. It will open the communication settings for this CPU. Here, first set

the Channel properties; the IP

address of your desktop. If not set properly, then you won’t be able to go

online in the HART device. Then, click BME_AHI_0812.

In the address setting tab, you have

to set the IP address of the module and it’s position in the CPU system. M is the notation for it’s local CPU

position and C is the notation for

it’s remote CPU position. Here, we used Mx80_02;

as our module is located in the 2nd slot of the local rack.

· Now, double click the BME_AHI_0812

option in the distributed bus as shown. It shows the overall HART settings

of the module. In the process data

tab, you can define which variables you want to read from the device. By

default, four variables are read from a device – PV, SV, TV and QV. In the parameter

configuration tab, you can define which channels are to enabled / disabled

for HART communication. In the security

tab, you have to disable the access

control option. This practice is normally done because sometimes, some

screens in the HART device don’t show proper records; when you go online in it.

Disabling this feature allows you to fully access all the windows inside the

HART device.

· Right click the BME_AHI_0812

option and add the HART device (DTM) in the channel you want.

After the PLC has been assigned with HART settings, you can now view it online. Refer the below video.

How to View HART device online in Unity Pro

I will

explain it in following steps:

· Right-click the module where the device has been connected

and click Connect. The module will

be highlighted in bold as shown in video.

· Again right-click the module and go to Device Menu -> Additional Functions -> Transfer to FDR Server. FDR

stands for Fast Device Replacement.

This service stores network and operation parameters of devices on the network.

If a device is replaced, the service automatically configures the replacement

device with parameters similar to those of the removed device. It is essential

to transfer the latest parameters to FDR server in the PLC; otherwise the bus state LED in the analog module will

blink and HART communication won’t happen properly.

· Right-click the channel where the device is connected and

click Connect. The device will show

as highlighted in bold; if the connection is proper.

· Double-click the device and you can see the overall

parameters of the device as shown in video. You can even configure the device

from this window.

In short,

you can overall control the actual device from just sitting in the centralized

PLC room and even configure it, if required, without going in the field. This

reduces your overall installation time and provides a greater control in the

system. Each and every parameter of the device can be viewed here through HART

communication.

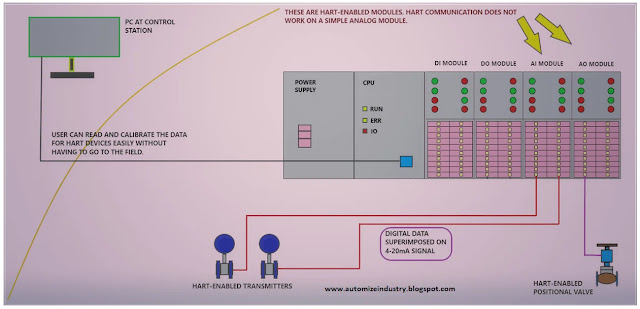

This lesson has been a basic introduction to the general

theory of HART communication. The ways the PLC analog I/O modules (HART-based)

are built differ between manufacturers and PLC models, so I have just covered

general principles without enough detail to implement them in any given PLC

system. I have also not attempted to cover every type of device. Each

manufacturer has unique ways of handling measurements, and there are many other

sorts of instruments that we have not included here.

Thank you guys; I hope you enjoyed reading the

practices normally used for this type of study in industrial automation. If you

have any views or know some more methods, then I would be happy to get a

comment from you.

Comments

Post a Comment

If you have any queries, please let me know