General Theory of Modbus Communication

1 June,

2020.

In this post, we will cover the basic topics on how to troubleshoot problems

faced by programmers in establishing modbus communication in Schneider PLC’s. We

will cover only Modbus RTU and TCPIP protocols here in RS-485 hardware. This

post is divided in two parts. Our first part will cover the general practices

used for Modbus communication. The next part will cover the practices of PLC’s

used in various Schneider softwares.

Modbus is the one of the most commonly used

communication protocols in industrial automation. It was developed by Modicon

in 1979 and was specifically designed for Modicon PLC’s (Now Schneider Electric).

Today, it is an open protocol and is available for a wide range of industrial

automation products. Modbus protocol is a messaging structure,

widely used to establish master-slave communication between intelligent

devices. A Modbus message sent from a master to a slave contains the address of

the slave, the 'command' (read register or write register), the data and

a checksum (LRC or CRC). Since it’s just a messaging protocol, it is

independent of the underlying physical layer.

Function Code in Modbus:

In a Modbus network, communication begins

when the master device sends a query to a connected slave. A slave device

spends its time monitoring the network for queries specifically addressed to

it. When a query is received, it will either perform an action or reply with a

response to the master. Queries are only initiated by the master device. This

brings function codes into picture. The function code in the request tells the

addressed slave device what kind of action to perform. The data bytes contains

any additional information that the slave will need to perform the function.

The general format of the data is – device address, followed by function code,

followed by register number, followed by register count, followed by data and

ending with checksum.

Modbus data

is most often read and written as "registers" which are 16-bit pieces

of data. Most often, the register is either a signed or unsigned 16-bit

integer. If a 32-bit integer or floating point is required, these values are

actually read as a pair of registers. The most commonly used register is called

a Holding Register, and these can be read or written. The other possible type

is Input Register, which is read-only. The exceptions to registers being 16

bits are the coil and the discrete input, which are each 1 bit only. Coils can

be read or written, while discrete inputs are read-only. Coils are usually

associated with relay outputs. The type of register being addressed by a Modbus

request is determined by the function code. The most common codes include 3 for

"read holding registers", and may read 1 or more. Function code 6 is

used to write a single holding register. Function code 16 is used to write one

or more holding registers. The function codes used commonly are:

|

Function Code |

Register Type |

|

1 |

Read Coil |

|

2 |

Read Discrete Input |

|

3 |

Read Holding Registers |

|

4 |

Read Input Registers |

|

5 |

Write Single Coil |

|

6 |

Write Single Holding Register |

|

15 |

Write Multiple Coils |

|

16 |

Write Multiple Holding

Registers |

For example, function code 03 will request

the slave to read holding registers and respond with their contents. The data

field must contain the information telling the slave which register to start at

and how many registers to read. The error check field provides a method for the

slave to validate the integrity of the message contents. If the slave makes a

normal response, the function code in the response is an echo of the function

code in the request. The data bytes contain the data collected by the slave,

such as register values or status. If an error occurs, the function code is

modified to indicate that the response is an error response, and the data bytes

contain a code that describes the error. The error check field allows the

master to confirm that the message contents are valid.

Types of Communication in Modbus:

Modbus uses three types of variations for

communication – RTU, ASCII and TCPIP. Modbus RTU uses binary coding and CRC

error checking. The basic difference between RTU and TCPIP is the physical

layer; RTU uses serial physical layer while TCPIP uses Ethernet physical layer.

ASCII uses ASCII characters to begin and end messages whereas RTU uses time

gaps (3.5 character times) of silence for framing. Modbus ASCII messages

require twice as many bytes to transmit the same content as a Modbus RTU

message.

Modbus

RTU uses three physical serial layers (electrical interfaces) to communicate –

RS232, RS422 and RS-485. RS-232 allows only single end-to-end communication

(one master and one slave). RS-422 and RS-485 allow point-to-multipoint communication

(one master with a maximum of 247 slave devices for RS-485 and 10 slave devices

for RS-422). One thing to remember is that a standard RS-485 protocol

communicates with only a maximum of 32 slave devices and to extend it further,

you require a repeater. RS-232 allows for data transfer at relatively slow

speeds (up to 20K bits/sec) and short distances (up to 50 ft). RS-422 allows

for higher speeds and relatively longer distances. But, it had it’s

disadvantages in not creating a true multipoint network; which is the reason why

RS-485 is the widely used interface nowadays. RS-485 can go up to 4000 ft. of

distance and achieve speeds of 10 Mb/s.

I will not go deep into this topic and you can find many sources in the

internet which will explain you in deep the differences between these three

physical layers. My point is to make you familiar with the general practices

used.

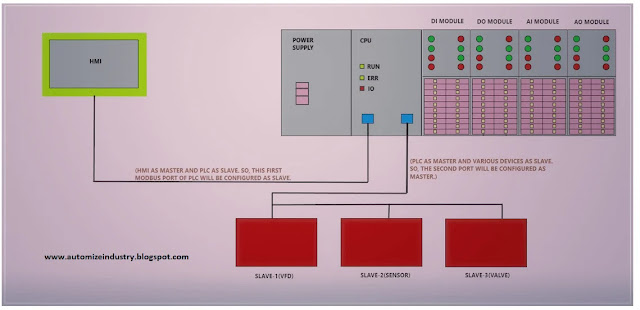

It

is also necessary to understand the topology used for Modbus RTU structure.

Refer the below image which must be used by programmers for establishing proper

communication.

Understanding Modbus Communication:

Many

programmers face issue in establishing Modbus connectivity in PLC. Before

proceeding for individual range of PLC’s, let’s have a look at the common steps

which must be undertaken in troubleshooting any Modbus port of Schneider range

of PLC’s.

·

The basic step a programmer

should check is to first verify the specifications of the Modbus device that he

is checking. It can be like; what is the physical interface that the device

uses and what are the parameters like parity, baud-rate, character format and

slave ID (in case the device is Modbus RTU). For Modbus TCPIP, only IP address

and slave ID of the device is required. The settings in PLC program must be

same as the device (apart from ID; otherwise communication will not happen. Keep

the document/technical catalogue of the device and PLC module ready for

testing. You must know what the registers available in the device for

communication are and how to address them properly.

·

Cable configuration and proper wiring is

must. Refer the below image which is used in standard practice:

Always refer the device and PLC catalogues

for their pin numbers. The connectors can be RJ45 type or DB9 type. Mostly,

communication can run even without a ground connection. But, it is recommended

to use it every time to avoid noise fluctuations. The voltage between neutral

and ground in the electrical panel should be in permissible limits (mostly less

than 2V). If you are facing more fluctuations, it is recommended to connect the

shield threads of the wire to a shielding point in the panel. Also, ensure that

there shouldn’t be any continuity between any of the pins as shown in figure.

· It is necessary to properly understand notations used for Modbus registers first of all. The address range applies to each type of register, and one need to look at the function code in the Modbus message packet to determine what register type is being referenced. The Modicon convention uses the first digit of a register reference to identify the register type. Register types and reference ranges recognized with Modicon notation are as follows:

0x = Coil = 00001-09999

1x = Discrete Input = 10001-19999

3x = Input Register = 30001-39999

4x = Holding Register = 40001-49999

On occasion, it is necessary to access more than 10,000 of a register type. Based on the original convention, there is another de facto standard that looks very similar. Additional register types and reference ranges recognized with Modicon notation are as follows:

0x = Coil = 000001-065535

1x = Discrete Input = 100001-165535

3x = Input Register = 300001-365535

4x = Holding Register = 400001-465535

When

using the extended register referencing, it is mandatory that all register

references be exactly six digits. Then only, the

difference can be identified between holding register 40001 and coil 40001. If coil 40001 is the target, it must

appear as 040001.

·

Extending it further, I would also like to

share one more point. Modbus protocol defines a register as 16-bit; however

there is a large scale demand in use for reading and writing data in more than

16 bits. The most common are IEEE 754 floating point and 32-bit integer. This

theory is also extended to double precision floating point and 64-bit integer. The

wide data simply consists of two consecutive "registers" treated as a

single wide register. Floating point in 32-bit IEEE 754 standard, and 32-bit

integer data, are widely used. Although the convention of register pairs is

widely recognized, agreement on whether the high order or low order register

should come first is not standardized. So, a wide number of softwares support a swap option. This means you simply

check the "swapped" option

if the other device treats wide data in the opposite order relative to the

software’s default order. In some cases, the “swap” option is more explicitly identified

as “high order data is in first register” or something to that effect.

·

Coming to the most important point, a

programmer must keep with him a USB-to RS485 converter; to test the Modbus

device or PLC. Also, there are various Modbus testing tools (softwares) in the

market. The most widely used is Modscan.

The programmer must have any of these softwares installed in his laptop. Corresponding

cable for the converter must also be kept ready. One must first check the master;

he must proceed to check slaves further.

·

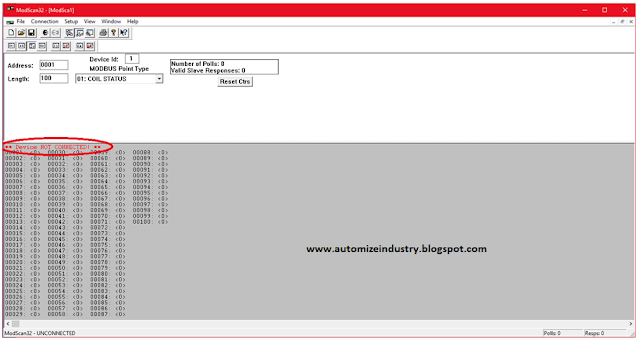

Refer the below images of Modscan software. The first one is for

Modbus RTU. Direct Connection to COM9 means

the communication port number of your laptop. You can find that in Device Manager – Ports section in your laptop. The configuration parameters must

match with that of the equipment you are testing. The second image is for

Modbus TCPIP. Enter the IP address of the device you are testing. The standard port for Modbus TCP is 502,

but port number can often be reassigned if desired.

Now, refer the below image after connection has been established. Address tab refers to the starting address of the register. Length tab refers to the number of registers that you want to view. Device ID tab refers to the unit ID of the device. Modbus Point Type refers to the function code that you want to work on. (For other function codes, you can use other softwares like ModbusPoll) As shown with red mark, if the device is properly connected with your PC, then it will show as Device Ok. When the device is connected, corresponding values will show in the registers. For coil status, only 0 or 1 will show in individual registers. (For example, 00001 can be 0 and 00002 can be 0 and 00003 can be 1)

If you want to deal with function codes 5,6,15 or 16; then I will explain you that too. For more simplicity, I will explain with the help of the given table below. Let us consider a fixed slave address with device ID as 5.

|

Function Code |

A Request Code |

Description |

|

1 |

05 01 0000 000B 0E84 |

This command is requesting on/off status

of discrete coils # 1 to 10 from the device. 05 – Slave ID (5 hex=address 5) 01 – Function Code 0000 – The data address of the first

coil to read (0 hex=0, +1 offset=coil#1) 000B – The total number of coils

requested (B hex=11, inputs 1 to 11) 0E84 – The CRC code |

|

2 |

05 02 0000 000B BAA9 |

This command is requesting on/off status

of discrete inputs # 1 to 10 from the device. 05 – Slave ID (5 hex=address 5) 02 – Function Code 0000 – The data address of the first

coil to read (0 hex=0, +1 offset=coil#1) 000B – The total number of coils

requested (B hex=11, inputs 1 to 11) BAA9 – The CRC code |

|

3 |

05 03 0000 000B 7687 |

This command is requesting data of

holding registers # 1 to 10 from the device. 05 – Slave ID (5 hex=address 5) 03 – Function Code 0000 – The data address of the first

register to read (0 hex=0, +1 offset=register#1) 000B – The total number of registers

requested (B hex=11, inputs 1 to 11) 7687 – The CRC code |

|

4 |

05 04 0000 000B B298 |

This command is requesting data of input

registers # 1 to 10 from the device. 05 – Slave ID (5 hex=address 5) 04 – Function Code 0000 – The data address of the first

register to read (0 hex=0, +1 offset=register#1) 000B – The total number of registers

requested (B hex=11, inputs 1 to 11) B298 – The CRC code |

|

5 |

05 05 0000 FF00 4E8B |

This command is writing a discrete coil

# 1 in the device. 05 – Slave ID (5 hex=address 5) 05 – Function Code 0000 – The data address of the coil to

write (0 hex=0, +1 offset=coil#1) FF00 – The status to write (FF00 hex=On,

0000 hex=Off) 4E8B – The CRC code |

|

6 |

05 06 0000 003C 9A9B |

This command is writing a single

register # 1 in the device. 05 – Slave ID (5 hex=address 5) 06 – Function Code 0000 – The data address of the register

to write (0 hex=0, +1 offset=register#1) 003C – The data to write (003C hex=60) 9A9B – The CRC code |

|

15 |

05 0F 0000 000A 02 CD01 BF0B |

This command is writing 10 coils # 1 to 9

in the device. 05 – Slave ID (5 hex=address 5) 0F – Function Code (0F hex=15) 0000 – The data address of the first coil

to write (0 hex=0, +1 offset=coil#1) 000A – The number of coils to write (0A

hex=10) 02 – The number of bytes to follow (10

coils means 2 bytes) CD01 – Coils #1 to 7(1100 1101=CD hex)

and coils #8 to 9(0000 0001=01 hex) BF0B – The CRC code |

|

16 |

05 10 0000 0003 06 0002 0004 0005 C6F0 |

This command is writing 3 registers # 1

to 3 in the device. 05 – Slave ID (5 hex=address 5) 10 – Function Code (10 hex=16) 0000 – The data address of the first

register to write (0 hex=0, +1 offset=register#1) 0003 – The number of registers to write

(03 hex=3) 06 – The number of bytes to follow (3 registers

of 16-bit each means 6 bytes) 0002 – Data to write in first register

(2=0002 hex) 0004 – Data to write in second register

(4=0004 hex) 0005 – Data to write in third register

(5=0005 hex) C6F0– The CRC code |

One more thing;

in our programming world, the most common techniques we cover are rebooting

(power recycle) of the device or laptop in worst scenario. I have covered the

general principles which normally are followed to troubleshoot modbus

connectivity issue. I have also not attempted to

cover every type of device. Each manufacturer has unique ways of handling

problems, and there are many other sorts of solutions that I have not included

here.

Thank you guys; we will cover the Modbus code troubleshooting for various

PLC’s used in Schneider in second part. If

you have any views or know some more methods, then I would be happy to get a

comment from you.

Thanks for shearing this kind of information modbus

ReplyDeleteThanks for shearing this kind of information modbus

ReplyDeleteThanks for shearing this kind of information modbus

ReplyDeleteI like your all post. You have done really good work. Thank you for the information you provide, it helped me a lot. crackroom.org I hope to have many more entries or so from you.

ReplyDeleteVery interesting blog.

Modbus Poll Crack

I like your all post. You have done really good work. Thank you for the information you provide, it helped me a lot. gurucrack.org I hope to have many more entries or so from you.

ReplyDeleteVery interesting blog.

Modbus Poll Crack

I thought this was a pretty interesting read when it comes to this topic. Thank you

ReplyDeleteModbus Poll Crack

SAM Broadcaster Pro Crack

Tally ERP Crack

Letasoft Sound Booster Crack

Dr Fone Crack

WindowManager Crack

Writing on trends is hard, but your blogs are doing this greatly. Winter Sale Jackets

ReplyDelete